Transfigure 1.0

Transfigure’s Mission:

Accelerate hardware development with AI models that create Physical Stuff.

My passion for engineering products is a gift refined through years of curiosity and dedication to the art of engineering. My goal is to unleash the joy of creation, accelerating the speed of hardware development, thus freeing humans to think carefully and creatively about improving the world we live in.

In over 20 years and thousands of parts designed, I have spent tens of thousands of hours with my engineering colleagues inventing complex electromechanical machines. In these endeavors, the great equalizer is time. Time is, under normal circumstances, a constant which we are all subject to. Time dictates when pencils must be down. Especially in the most urgent situations, the finality of time means there is often not enough of it, even with the best talent.

The Present:

Hardware takes months, years, and sometimes decades to bring to production. This R&D effort costs $3T globally each year. Why is this? Product design is gated by the sheer number of clicks, keystrokes, and mouse movements of humans inputting the most basic information into a computer. Transferring a mechanical design from napkin sketch to CAD software is burdensome and does not add value. At present this is a necessary burden, ensuring the downstream customer receives the precise information necessary to manufacture a physical part. For decades, this has been the status quo.

Consider The Future:

Transfigure’s AI models, trained on the equivalent of several decades of human efforts, directly build high quality, trustworthy CAD models in less than a minute, replacing $1T of labor units. Napkin sketches directly become full context cars, robots, and tools. Architectural drawings directly become full context buildings, interiors, landscapes. Industrial designs directly become household goods and consumer electronics. Eventually, AI robots directly create the next, better version of themselves. An AI model that designs physical stuff.

The urgency of Transfigure’s mission is not that present-day engineers are incapable or lazy. Rather, the advent of AI algorithms and hardware give hardware engineers tools to accelerate hardware design by 100 or 1000 times, matching the output of their software engineering colleagues who were the first to benefit from AI just a couple years ago. A Transfigure powered mechanical engineer that produces 200 times that of their colleague, can reduce over $20M worth of labor units for a large project. Multiplied across an entire workforce globally, this trillion dollar savings can either increase profit margins or be re-invested into R&D, paying higher wages to improve lives, or building more efficient factories.

Transfigure is not alone:

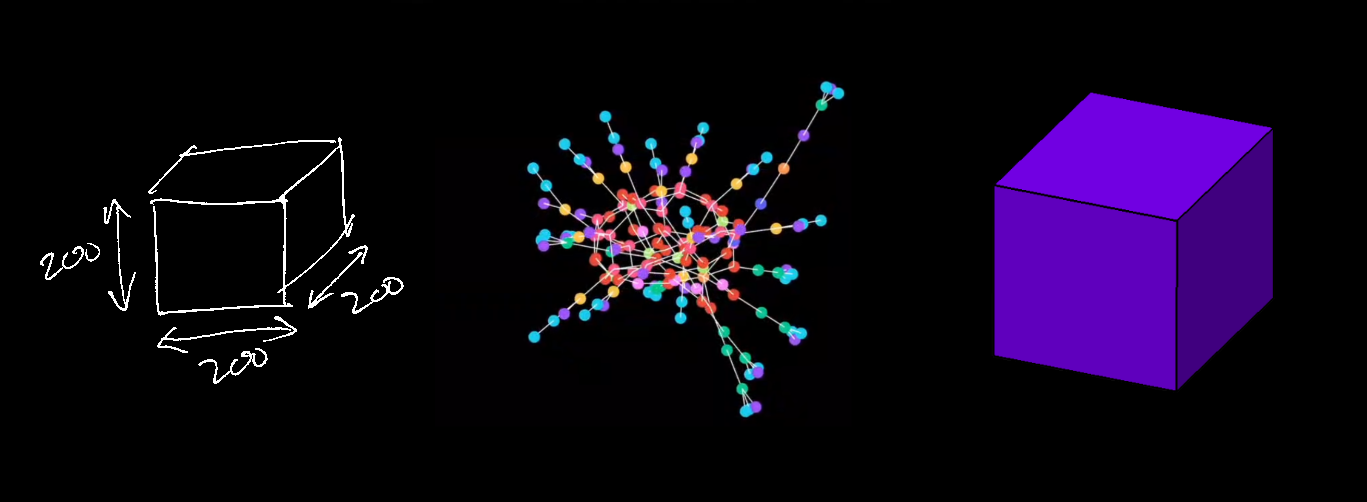

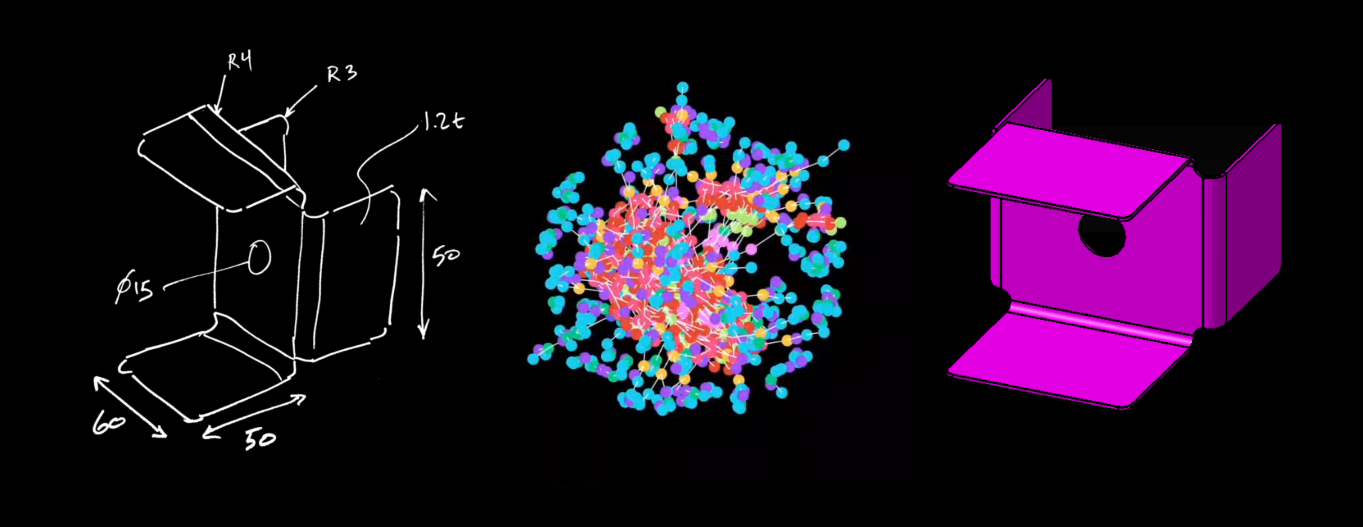

To date, two methods have been pursued to generate 3D data using AI. The first method creates point cloud mesh data based on text prompts and relies on general understanding of the shape of objects (a ball, banana, balloon). Mesh data is only approximate 3D data and it is too coarse for the creation of molds, dies, and toolpaths used in manufacturing. The second method creates generic 3D B-rep data based on a text prompt. The amateur output and un-natural prompting of this method is actually worse than the industry standard tools available today and will never see industry adoption due to its lack of precision.

Transfigure will be the best:

Transfigure’s new AI model will directly create high quality output, ready for production, in industry standard formats, based on a human engineer’s natural input i.e., a napkin sketch. The engineer is still in charge: Human over machine. Transfigure’s philosophy is to rely on the ingenuity and creativity of the human spirit to create new physical products more quickly using AI at the highest quality and speed afforded by available compute.

Transfigure is tackling 3D data first, but not stopping there. CAD data comes in many forms and disciplines: 2D and 3D, mechanical and electrical, serving as the blueprint for people and factories to build everything we feel, touch, and use to drive our economy. A simple sketch becomes a complete product, with all physical parts, in minutes. With this in mind, take a glance around your house, and feel humbled by the cumulative millions of hours of computer work behind your food, shelter, comfort, and convenience. The opportunity is huge: Transfigure’s grand ambition is to 1000x the speed of designing literally everything.

Achieving the mission will require three areas of success:

The Right Team:

Transfigure will only hire and retain the best talent in order to maintain capital efficiency and preserve the magic X-factor multiplier that large companies dream of but will never achieve. Hiring the best talent also means hiring the best culture, and only trustworthy individuals with high initiative and respect for their fellow teammates and customers will be allowed in the fold. At Transfigure, the direct intersection of pure software engineering and pure mechanical engineering will require individuals with deep sympathy for each other's field of expertise. Culture > Raw talent, because that is where the magic happens.

Pure Ingredients for a Trustworthy Model:

Transfigure’s AI model will require an unprecedented combination of computer vision, long sequence lengths, massive contexts, and numerical precision. Finite element models, machinists, and tool shops require and depend on high quality CAD. Transfigure’s perfect, proprietary training data is the secret sauce that ties the model together. Most importantly, the training data will be authentic: Parts and designs that a real hardware engineer would actually be proud of.

A Joy to use:

Joy is marked by a feeling of great happiness or pleasure. This is a metric Transfigure will use in two ways: 1. To measure the quality of Transfigure’s AI model output and successful integration with existing product design workflows, and 2. To measure the likelihood that a user will want to use Transfigure over and over again. Ensuring a user experiences these types of joy is directly related to Transfigure’s ability to penetrate the market, have repeat customers, affect real change, and thereby generate massive revenue. In summary: When Transfigure brings joy to the customer, I will deem this mission a success.

Why:

There is no question that the world needs Transfigure to exist: Hardware engineers and companies receive minimal benefit from AI while software engineers receive the lions share of attention and progress. CEOs bemoan high costs of labor while politicians complain of off-shoring. The ability of companies and nations to compete on the global stage with healthy GDP growth relies on the ability to make physical stuff faster, representing at least half of the world’s $110T GDP.

Designing and building hardware is time consuming. The likelihood of an engineer, a company, or a country to quickly secure dominance over competitors depends on proactively defending and improving the productivity and labor unit cost of a given population. Transfigure exists to do just that, in the physical world, using AI not to work smarter or harder, but faster.

Engineering is by nature hard work, and Transfigure is going to make this happen faster with less labor and a lot more fun. Let’s go!